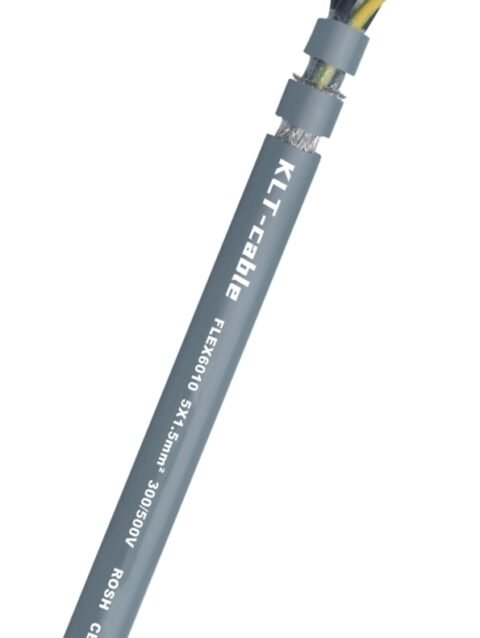

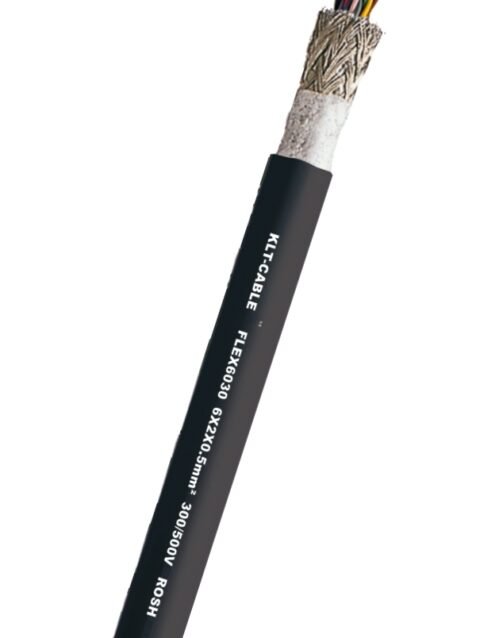

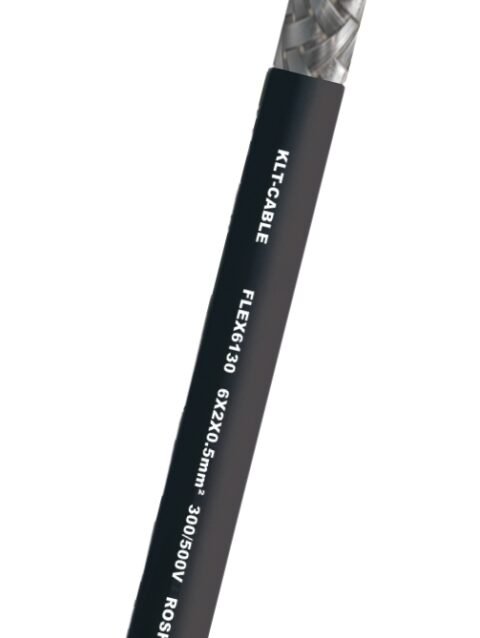

FLEX600 Medium speed PVC sheathed flexible energy chain special single core cable

FLEX600 (TRV) is used to connect mobile devices such as elevators, electric doors, cranes, etc., instead of rubber insulation and sheathed cables, improving environmental conditions and reducing weight.

Other types of ultra-soft wires can be used to form extra-flexible cables, or they can be composed of different specifications of extra-soft wires, which can be braided and shielded.

CE= products comply with the EU Low Voltage Directive 2014/35/EU

application

FLEX600 (TRV) is used to connect mobile devices such as elevators, electric doors, cranes, etc., instead of rubber insulation and sheathed cables, improving environmental conditions and reducing weight.

Other types of ultra-soft wires can be used to form extra-flexible cables, or they can be composed of different specifications of extra-soft wires, which can be braided and shielded.

CE= products comply with the EU Low Voltage Directive 2014/35/EU

peculiarity

- Very good flexibility

- Small bending radius

- The outer sheath can be reinforced

Product structure

| conductor | Fine bare copper multi-stranded wire (according to DIN EN 60228) |

|---|---|

| insulation | PVC mixture with high mechanical properties |

| Core color | With a black core with a continuous number, compliant. Meets EN 50334 + VDE 0293-334 with > 3 cores with green and yellow ground wire |

| shield | Optional |

| Sheath material | If available (low-viscosity, PVC-based mixture), it is suitable for energy chains |

| Sheath color | Black (RAL 9005) Other colours available on request |

Technical parameters

| Operating voltage | Uo/U 300/500 V ; 450/750V ; 0.6/1 kV |

|---|---|

| Test voltage | 核芯/核芯 1000V ; 1500V ; 4000 V |

| Bending radius | Fixed laying 7xd

Non-energy chain in-chain 10xd 12.5xd in the energy chain |

| Temperature range | Fixed laying: -15/+70 °C

Continuous flexibility: -5/+90 °C Continuous flexibility: +5/+90 °C |

| Movement speed | Overhead 1 mls |

| acceleration | 10 mls |

| Travel distance | Overhead with a distance of less than 10 meters |

Cable parameters

| numbering | specification | Monofilament max. | Cable diameter – ø ± 5% | Copper weight | Finished product weight | |

|---|---|---|---|---|---|---|

| L6166 .. 82* | 1.5 mm² | 0.26mm | 3.2mm | 14.4Kg/Km | 23Kg/Km | Send an inquiry |

| L6166 .. 84* | 2.5 mm² | 0.26mm | 3.9mm | 24Kg/Km | 35Kg/Km | Send an inquiry |

| L6166 .. 86* | 4 mm² | 0.31mm | 4.5mm | 384Kg/Km | 51Kg/Km | Send an inquiry |

| T6166 .. 87* | 6 mm² | 0.31mm | 5mm | 576Kg/Km | 71Kg/Km | Send an inquiry |

| T6166 .. 88* | 10 mm² | 0.41mm | 7,3mm | 96Kg/Km | 131Kg/Km | Send an inquiry |

| T6166 .. 89* | 16 mm² | 0.41mm | 8,3mm | 153.6Kg/km | 199Kg/Km | Send an inquiry |

| T6166 .. 90* | 25 mm² | 0.41mm | 10,2mm | 240Kg/Km | 305Kg/Km | Send an inquiry |

| T6166 .. 91* | 35 mm² | 0.41mm | 11,4mm | 336Kg/Km | 404Kg/Km | Send an inquiry |

| T6166 .. 92* | 50 mm² | 0.41mm | 14,1mm | 480Kg/Km | 576Kg/Km | Send an inquiry |

| T6166 .. 93* | 70 mm² | 0.41mm | 15,1mm | 672Kg/Km | 765Kg/Km | Send an inquiry |

| T6166 .. 94* | 95 mm² | 0.51mm | 18,5mm | 512Kg/Km | 1052Kg/Km | Send an inquiry |

| T6166 .. 95* | 120 mm² | 0.51mm | 20mm | 1152Kg/Km | 1261Kg/Km | Send an inquiry |

| T6166 .. 96* | 150 mm² | 0.51mm | 221mm | 1440Kg/Km | 1567Kg/Km | Send an inquiry |

| T6166 .. 97* | 185 mm² | 0.51mm | 23,5mm | 1776Kg/Km | 1892Kg/Km | Send an inquiry |

| T6166 .. 98* | 240 mm² | 0.51mm | 272mm | 2304Kg/Km | 2538Kg/Km | Send an inquiry |