3-2 MMS

EN 50264-3-2 MMS 0.6/1 kV shielded multi-core power cable

Application

EN 50264-3-2 MMS multi-core shielded power and control cables are suitable for protected installations requiring enhanced electrical shielding (electromagnetic compatibility). This product range is recommended for installations and connections in tight spaces, where optimal bending radii are required. Cables are designed to withstand harsh operating conditions (oil, ozone, temperature changes, etc.). Allows the conductor temperature to reach 120°C during a cumulative operating time of 20,000 hours.

CE= The product complies with the provisions of the European Union Low Voltage Directive 2014/35/EU

Features

- Halogen-free

- Low smoke emission properties

- Excellent flame retardant properties High temperature resistance properties

- Good chemical resistance Fire resistance and flame retardant properties

- Conductor temperature: -40°C / +90°C / +120°C

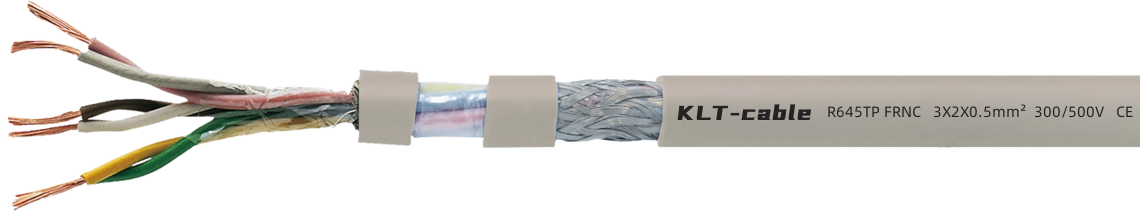

Construction

| Conductor |

Flexible stranded construction Tinned copper conductor conforming IEC/EN 60228 Category 5 standard Optional isolation tape |

||

|---|---|---|---|

| Insulation |

EI type 109 cross-linked compound Conforming to EN 50264-1 |

||

| Shielding | Tinned copper braid | Optional isolation tape | |

| Outer sheath |

EM type 104 cross-linked compound Conforming to EN 50264-1 Resistant to oil, diesel, ozone and UV |

||

|

SheathColor |

Black |

||

| Color coding |

Insulation: black Core identification by white printed numbers |

Technical data

| Test voltage | 0.6/1 kV | ||||

| Bending radius |

Fixed laying: 4xD Flexible use: 8xD |

||||

|---|---|---|---|---|---|

| Temperature range | – 40°C +90°C | ||||

| Fire performance |

EN 50306 cables comply with the EN 45545-2 standard and are designed to pass the fire test of NFPA 130 |

||||

| Usage guide | Allowable ampacity and wiring rules are found in EN 50355 and EN 50343 | ||||

| Certification standards |

IEC/EN 61034-2 (Smoke density test) IEC/EN 60332-1 (single cable vertical burning) IEC/EN 60332-3 (bundled cable burning test) EN 50305-9.1 (Special test for railway applications) |

||||

| Flexibility |

Very good |

||||

| Environmentally friendly |

Compliant with EU RoHS directive |

Dimensions

| No. | Specifications | Cable MAX diameter -ø ± 10% | Weight | |

|---|---|---|---|---|

| 1P0198 | 3x 1.5mm² | 9.3mm | 120kg/km | |

| 1P0199 | 4x1.5mm² | 10.5mm | 150kg/km | |

| 1P0200 | 3 x 2.5mm² | 10.4mm | 150kg/km | |

| 1P0201 | 4x 2.5mm² | 11.7mm | 205kg/km | |

| 1P0202 | 3x 4mm² | 12.5mm | 225kg/km | |

| 1P0203 | 4x 4mm² | 14.0mm | 300kg/km | |

| 1P0204 | 3x 10mm² | 18.0mm | 530kg/km |

.Other sizes and colors are available upon request. The above data are for reference only, and the actual product shall prevail.