SD 93P

PVC insulated/PUR sheathed control drag chain cable, shielded 300/500V

Application

W-S90 is a continuous flexible PUR data cable with a colored core that has increased efficiency due to the use of millions of bending cycles. This highly flexible cable is recommended for use in loading and unloading, material handling and automation technology, wood processing and packaging machines, welding machines and cutting systems.

CE= Product complies with the EU Low Voltage Directive 2014/35/EU

Features

- Very good flexibility

- Small bending radius

- Oil resistance

- High tear resistance

- Good chemical resistance (acid resistance)

- Bending life >15 million times

Remarks

Also available in size 050 on requestmm²and 075mm²!

Construction

| Conductor |

Bare copper stranded conductor complies to IEC 60228, VDE 0295, Class 6 standards |

|---|---|

| Insulation |

PVC, TI2 complies. Conforms to EN 50363-3 + VDE 0207-363-3 |

| Core color |

With consecutively numbered black core wires, compliant. Conforms to EN 50334 + VDE 0293-334, >3 cores with green and yellow ground wire |

| Structure |

Each layer is specially adjusted with non-woven tape for layering |

| Wrapping |

Non-woven tape |

| Shielding |

None |

| Sheath material |

PUR, TMPU complies with EN 50363-10-2 + VDE 0207-363-10-2 standards, with matte surface (model S90 is glossy PUR) |

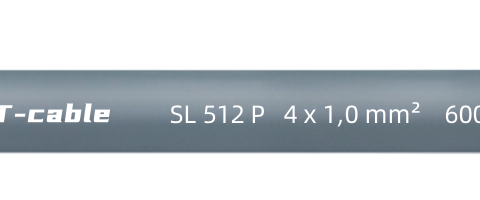

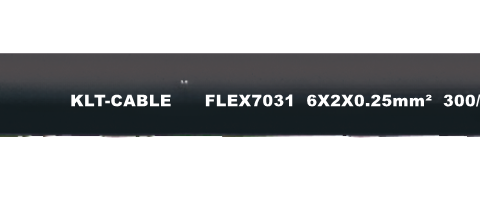

| Sheath color |

Gray (RAL 7000) Other colors on request |

Technical data

| Operating Voltage |

max. 350 V |

|---|---|

| Test Voltage |

Core/Core 1500 |

| Bending Radius |

Continuous Flexibility: 7,5,10D |

| Radiation Resistance |

5 x 10⁷ cJ/kg |

| Temperature Range |

Occasionally flexible: -30/+70°C Continuously flexible:: -5/+70°C |

| Oil Resistance |

Very good – TMPU complies with EN 50363-10-2 + VDE 0207-363-10-2 |

| Chemical Resistance |

Resistant to acids, alkalis, solvents, hydraulic fluids, etc. |

| Flexibility |

Very Good |

| Environmentally Friendly |

EU RoHS Compliant |

Dimensions

| No. | Specifications | monofilament max. | Cable Diameter -ø ± 5% | Copper weight | Finished product weight | |

|---|---|---|---|---|---|---|

| L07780201 | 2 x 0,14 mm² | 0.11mm | 3.3mm | 2,7 kg/km | 12kg/km | |

| L07780301 | 3 x 0,14 mm² | 0.11mm | 3.5mm | 4kg/km | 14kg/km | |

| L07780401 | 4 x 0,14 mm² | 0.11mm | 3.7 mm | 5,4 kg/km | 17kg/km | |

| L07780501 | 5 x 0,14 mm² | 0.11mm | 4 mm | 6,7 kg/km | 20kg/km | |

| L07780701 | 7 x 0,14 mm² | 0.11mm | 4.6mm Meters | 9,4 kg/km | 2 7kg/km | |

| L07781201 | 12 x 0,14 mm² | 0.11mm | 5 mm | 16.1 kg/km | 38 kg/km | |

| L07781801 | 18 x 0,14 mm² | 0.11mm | 6.3mm | 24.2 kg/km | 54 kg/km | |

| L07782501 | 25 x 0,14 mm² | 0.11mm | 7,5mm | 33.6 kg/km | 70 kg/km | |

| L07780202 | 2 x 0,25 mm² | 0.11mm | 3.5mm | 4,8 kg/km | 15 kg/km | |

| L07780302 | 3 x 0,25 mm² | 0.11mm | 3.8 mm | 7,2 kg/km | 19 kg/km | |

| L07780402 | 4 x 0,25 mm² | 0.11mm | 4.1 mm | 9,6 kg/km | 23 kg/km | |

| L07780502 | 5 x 0,25 mm² | 0.11mm | 4.4mm | 12kg/km | 28 kg/km | |

| L07780702 | 7 x 0,25 mm² | 0.11mm | 5.1 mm | 16,8 kg/km | 38 kg/km | |

| L07781202 | 12 x 0,25 mm² | 0.11mm | 6,1mm | 28.8 kg/km | 54 kg/km | |

| L07781802 | 18 x 0,25 mm² | 0.11mm | 7,1 mm | 43.2 kg/km | 78kg/km | |

| L07782502 | 25 x 0,25 mm² | 0.11mm | 8,6 mm | 60 kg/km | 106 kg/km | |

| L07780203 | 2 x 0,34 mm² | 0.11mm | 4.2mm | 6.5 kg/km | 21kg/km | |

| L07780303 | 3 x 0,34 mm² | 0.11mm | 4.4mm | 9,8 kg/km | 25kg/km | |

| L07780403 | 4 x 0,34 mm² | 0.11mm | 4.8mm | 13.1 kg/km | 31kg/km | |

| L07780503 | 5 x 0,34 mm² | 0.11mm | 5.2mm | 16.3 kg/km | 38 kg/km | |

| L07780703 | 7 x 0,34 mm² | 0.11mm | 6,1mm | 22.8 kg/km | 52kg/km | |

| L07781203 | 12 x 0,34 mm² | 0.11mm | 7,3 mm | 39.2 kg/km | 74kg/km | |

| L07781803 | 18 x 0,34 mm² | 0.11mm | 8,8 mm | 588 kg/km km | 112 kg/km | |

| L07782503 | 25 x 0,34 mm² | 0.11mm | 10,4mm | 81.6 kg/km Miles | 147 kg/km |

Other sizes and colors are available upon request. The above data are for reference only and the actual product shall prevail.