SV 601CP

PUR sheathed TPE inner core power line + control line combination motor connection cable 0.6/1 kV total shielding + sub-shielding

Application

SL601C is a combined TPE/PUR motor connection cable with integral copper shielding 0.6/1 kV. Recommended for highly flexible cable rail applications in smart industry with servo drives, such as cable rails in automation technology, machine building, construction of industrial robots and factories, power, control and manufacturing engineering, handling systems, the automotive manufacturing industry, and carpentry centers. Additionally, it is color-coded.

CE= Product complies with the EU Low Voltage Directive 2014/35/EU

Features

- Suitable for cable drag chains

- Very high flexibility

- Very good EMC properties

- Oil resistant

- Long service life

- Adhesion-free installation

- Halogen-free

- Elastic at low temperatures

Remarks

- Composite cables can be customized on request

Construction

| Conductor |

Bare copper wire in compliance with IEC 60228, VDE 0295, Category 6 standards ,>0,5 mm² according to VDE 0812 |

|---|---|

| Insulation |

Thermoplastic elastomer |

| Inner core color |

Black wire core with consecutive numbers, in compliance with EN 50334 + VDE 0293-334 standards (0.34 mm² = except color) and green-yellow ground wire

From product number 08011415 Start: Power wires: U1, V2, W3 and green-yellow ground wire Control cores: BR1 and BR2 |

| Construction |

Control wire cores 0.34 mm2 – 2.5 mm2 twisted pair |

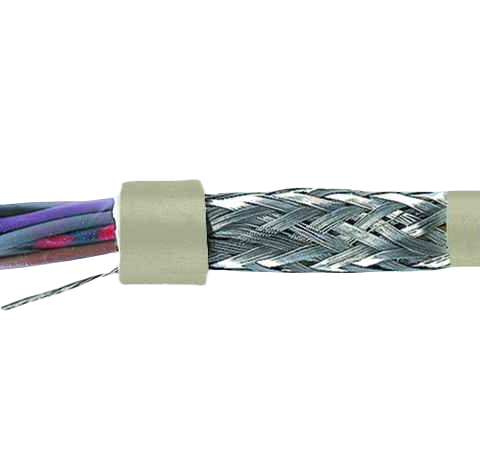

| Shielding |

Pairs wrapped in aluminum foil, tinned copper braid |

| Sub-wrapping |

with PETP Foil pairing |

| Construction |

Shielded control wire pairs and supply wire cores twisted layer by layer |

| Outer wrapping |

Non-woven tape |

| Screen |

Tinned copper braid |

| Packaging |

Non-woven tape |

| Sheath material |

PUR, TMPU in compliance with EN 50363-10-2 + VDE 0207-363-10-2 standards, rough surface |

| Sheath color |

Orange (RAL 2003) |

Technical data

| Operating Voltage |

Power supply core: Uo/U 0.6/1 kV |

|---|---|

| Peak operating voltage |

Control core: max. 500 V |

| Test Voltage |

Supply core: Core/core 4000 V Core/shield 4000 V

Control core: Core/core 1500 V Core/shield 1200 V |

| Minimum bending radius |

Fixed installation: 5xd Flexible application: 10 xd Continuous flexible: 12 xd |

| Radiation Resistance |

5 x 10⁷cJ/kg |

| Temperature Range |

Fixed installation: -50/+90°C Flexible application: -40/ +90°C |

| Oil Resistance |

Very good – TMPU complies with EN 50363-10-2 + VDE 0207-363-10-2 standards |

| Chemical Resistance |

Resistant to acids, alkalis, solvents, hydraulic oils, etc. |

| Weather Resistance |

Very Good |

| Environmentally Friendly |

CompliantEURoHS Directive |

Dimensions

| Number | Description | Specifications | Maximum Single wire diameter |

Outer diameter -ø | Bronze statue | Cable weight ≈ | |

|---|---|---|---|---|---|---|---|

| L08010407 | 4 x 0.75 mm² + 2 x (2 x 0.34 mm²) | 0,16/0,11 mm | 10.5±0.5 mm | 115.5 kg/km | 160 kg/km | ||

| L08010410 | 4 x 1,00 mm² + 2 x (2 x 0,75 mm²) | 0,16 mm | 12,0 ± 0,5 mm | 154,2 kg/km | 209kg/km | ||

| L08010415 | 4 x 1.50 mm² + 2 x (2 x 0.75 mm²) | 0,16 mm | 12.2±0.5mm | 174.3kg/km | 233kg/km | ||

| L08010425 | 4 x 2,50 mm² + 2 x (2 x 1,00 mm²) | 0,16 mm | 15,0 ± 0,8 mm | 236,8kg/km | 312kg/km | ||

| L08010441 | 4 x 4,00 mm² + (2 x 1,00 mm²) + (2 x 1,50 mm²) | 0,16 mm | 17.8±0.6 mm | 349,8 kg/km | 463kg/km | ||

| L08010461 | 4 x 6,00 mm² + (2 x 1,00 mm²) + (2 x 1,50 mm²) | 0,21/0,16 mm | 18.6±0.8 mm | 437.6kg/km | 580kg/km | ||

| L08010471 | 4 x 10,00 mm² + (2 x 1,00 mm²) + (2 x 1,50 mm²) | 0,21/0,16 mm | 22.5±1.0 mm | 613,5kg/km | 792kg/km | ||

| L08010485 | 4 x 16,00 mm²+ 2 x (2 x 1,50 mm²) | 0,21/0,16 mm | 27.6±0.8 mm | 880,6 kg/km | 1130kg/km | ||

| L08010490 | 4 x 25,00 mm² + 2 x (2 x 1,50 mm²) | 0,21/0,16 mm | 28,0 ± 1,0 mm | 1237,0 kg/km | 1507kg/km | ||

| L08010495 | 4 x 35,00 mm² + 2 x (2 x 1,50 mm²) |

0,21/0,16 mm | 32,0 ± 1,0 mm | 1647,3kg/km | 2011kg/km | ||

| L08010496 | 4 x 50,00 mm² + 2 x (2 x 2,50 mm²) | 0,21/0,16 mm | 38.2±1.0mm | 2324,0 kg/km | 2866kg/km | ||

| L08011415 | Siemens | 4 x 1.50 mm² + (2 x 1.50 mm²) | 0,16 mm | 12.5±0.4 mm | 161,8kg/km | 213kg/km | |

| L08011425 | Siemens | 4 x 2,50 mm² + (2 x 1,50 mm²) | 0,16 mm | 13.8±0.4 mm | 202,1kg/km | 266kg/km | |

| L08011440 | Siemens | 4 x 4,00 mm² + (2 x 1,50 mm²) | 0,16 mm | 14.9±0.4 mm | 270,4 kg/km | 353kg/km | |

| L08011460 | Siemens | 4 x 6,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 16.7±1.1 mm | 382,5kg/km | 490kg/km | |

| L08011470 | Siemens | 4 x 10,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 19.2±1.6 mm | 549,4 kg/km | 698kg/km | |

| L08011480 | Siemens | 4 x 16,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 23,0 ± 1,7 mm | 802,2kg/km | 1008kg/km | |

| L08011490 | Siemens | 4 x 25,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 26.9±1.0 mm | 1171,1kg/km | 1448kg/km | |

| L08011495 | Siemens | 4 x 35,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 31,0 ± 1,0 mm | 1592.3kg/km | 2012kg/km | |

| L08011496 | Siemens | 4 x 50,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 34.8±1.0 mm | 2203.3kg/km | 2695kg/km |

Other sizes and colors are available upon request. The above data are for reference only and the actual product shall prevail.